日本HAMMER MILL

2022-11-03T12:11:39+00:00

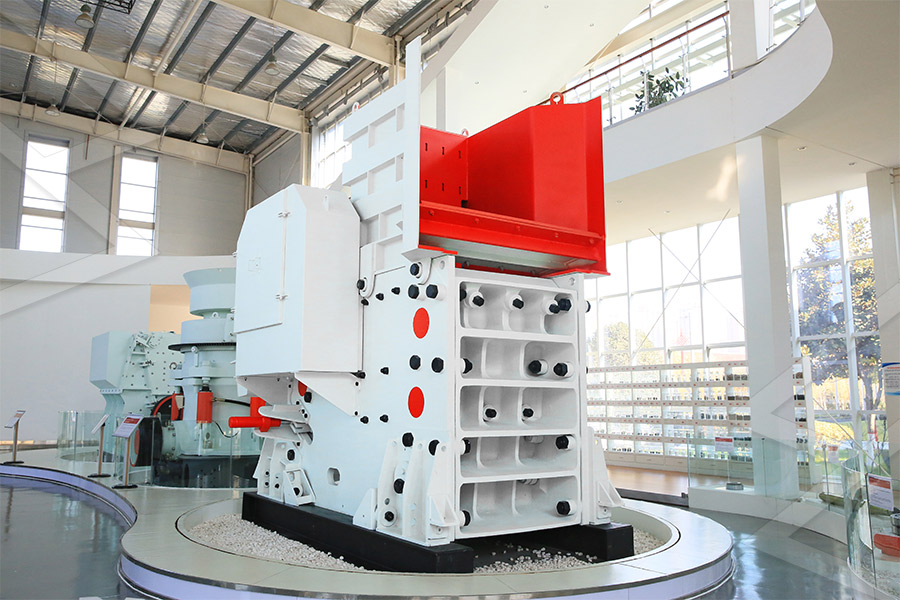

Horizontal Hammer Mill Grinding System Group

WebHammer Mill Grinding With over 160 years of industry experience and continued cutting edge research and development, is proud to present the next generation grinding portfolio, with all new and updated A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers These machines have numerous industrial applications, including: • Ethanol plants (grains)• A farm machine, which mills grain into coarse flour to be fed to livestockHammermill Wikipedia

Particle Size Reduction Equipment Schutte Hammermill

WebLeading manufacturer of custom designed size reduction equipment, including hammer mills, shredders, lump breakers, crushers, and replacement parts Request A Quote 1 WebThe Traveling Breaker Plate Mill is a nonclog hammer mill This engineering allows a Slugger Crusher to reduce rock, clay, shale, and bauxite to less than ¾” It can reduce wet, sticky materials to a size Hammer Mills for Material Reduction Williams Patent Crusher

Hammer mill Wikipedia

WebA hammer mill, hammer forgeor hammer workswas a workshopin the preindustrial erathat was typically used to manufacture semifinished, wrought ironproducts or, sometimes, WebHammer mills are typically used in large industrial processes requiring a high throughput while guaranteeing relatively fine product Some robust design can be found in mining industries, while other suppliers have Hammer mills : Overview Buying guide

Fitzpatrick Powder Milling Equipment

WebHammer Mills use mechanical 'inair' impact forces to transform bulky raw materials into uniform particles The key variables controlling particle size are rotor speed, screen size geometry and feed throat Fitzpatrick WebHuber operates in more than 20 countries around the world Learn more about the global locations of JM Huber Corporation and our portfolio companiesOur Global Locations Huber

Tool Service Company Marietta, GA 30060

WebWelcome! Tool Service Company was founded in 1947 and is well known in the Atlanta area for quality tool repair We service all major brands of pneumatic, electric, and hydraulic WebPrater hammer mills are the premier choice for applications requiring high capacities, operational efficiency, and uniform particle size distributions All five Prater FullScreen hammer mills are equipped with our proprietary Hammer Mills and Material Size Reduction Equipment

Fine Grinders, Hammer Mills, and More for Particle Size Reduction

WebIf your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been designing, manufacturing and creating innovative solutions for large and small customers all over the worldWebHammer Mill HM 200 Rugged design meets high final fineness Hammer mills are used for crushing, pulverizing and deagglomeration of mediumhard, hard, brittle, tough and fibrous samples The rugged RETSCH Hammer Mill HM 200: For Laboratory Pilot Plant ::

Fitzpatrick Powder Milling Equipment

WebHammer Mills use mechanical 'inair' impact forces to transform bulky raw materials into uniform particles The key variables controlling particle size are rotor speed, screen size geometry and feed throat Fitzpatrick WebFeb 25, 2016 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion Hammer Mill Crusher Grinder Mineral Processing

Hammer mill Wikipedia

WebA hammer mill, hammer forge or hammer works was a workshop in the preindustrial era that was typically used to manufacture semifinished, wrought iron products or, sometimes, finished agricultural or mining tools, or military weapons The feature that gave its name to these workshops was the waterdriven trip hammer, or set of hammers, used in the WebJun 15, 2020 Hammer mills can effectively reduce raw material to desired sizes as needed, from mediumsized particles to ultrafinesized particles Whether food pellets for livestock feed, granules of sugar, spices or Understanding the Working Principle of Hammer Mills

Hammer Mills Heavy Duty (HD) Class Mt Baker

WebThe 34″ x 24″ HD hammer mill is rated to accept feed of this type of looselyheld material at up to 20lbs per piece The 24″ x 16″ HD hammer mill is good for up to 68 lbs per piece We recommend that heavy WebHammermill Crushers are known to generate material finer than 3/16" (4mm), which in some applications may be undesirable However, if there is a market for finer material, or if it is acceptable within the desired product size, Hammermills can achieve reduction ratios that may otherwise require multiple crushersHammermill Crushers McLanahan

Which Mill System Should I Buy? Blog Fluid Air

WebJet mills, impact mills, screening mills, cone mills, ball mills and hammer mills are just a few of the different operational classes of mills available, and if you’re unfamiliar with the terminology involved, this can be especially confusing Here are a few things to look for to help you determine which mill might be best for your application 1WebSteel hammer mill grinding machine Mfd by Schepens (Belgium), Type Gladiator, Size 3 Shaft speed 4500 rpm W/ (16) swing hammers Chamber 300mm dia x 250mm wide Feed 250mm x 100mm Feed end has Erietz magnetic Princeton Junction, NJ Click to Request Price Trusted Seller Williams Patent Crusher Pulverizer Co Meteor 40 High Speed Used Hammermill pulverizers Machinio

A Brief History of the Hammermill West Salem Machinery

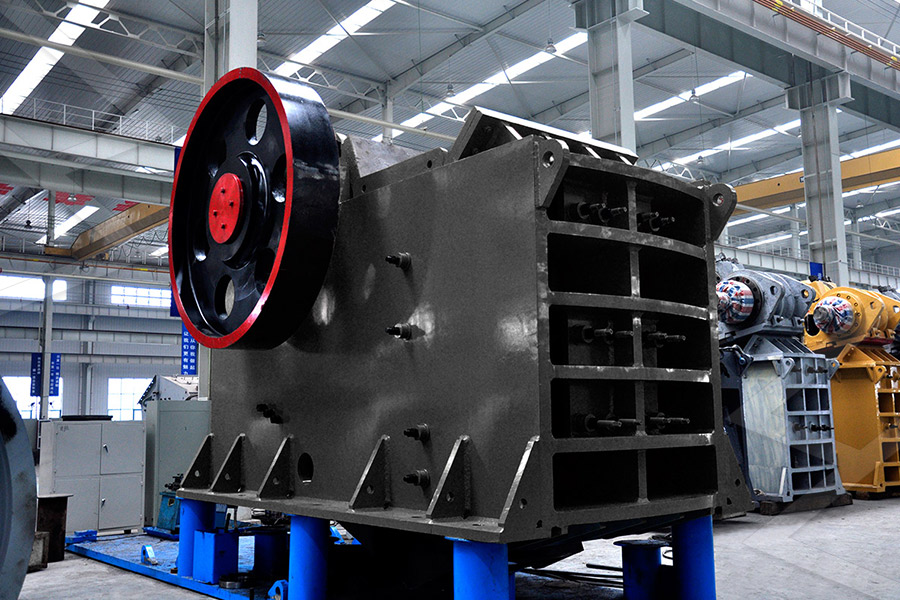

WebJul 29, 2022 The history of the hammermill dates back over 1,500 years to the 5 th century Unlike the hammermills used today, these machines were most often used to create weapons or for mining In 488 AD, the Chinese inventor and engineer Zu Chongzhi invented a waterpowered hammermill The increased power generated by powerful river currents WebA hammer mill is a singlepassagetype mill that has sets of hammers (generally rectangular pieces of hardened steel) spaced equally and attached to a rotating shaft that rotates at high speed using a powerful electric motor inside a grinding chamber The leading face of the hammers may be blunt or sharp to create different impact or shearing Hammer Milling Baking Processes BAKERpedia

Hammer Mills FEECO International Inc

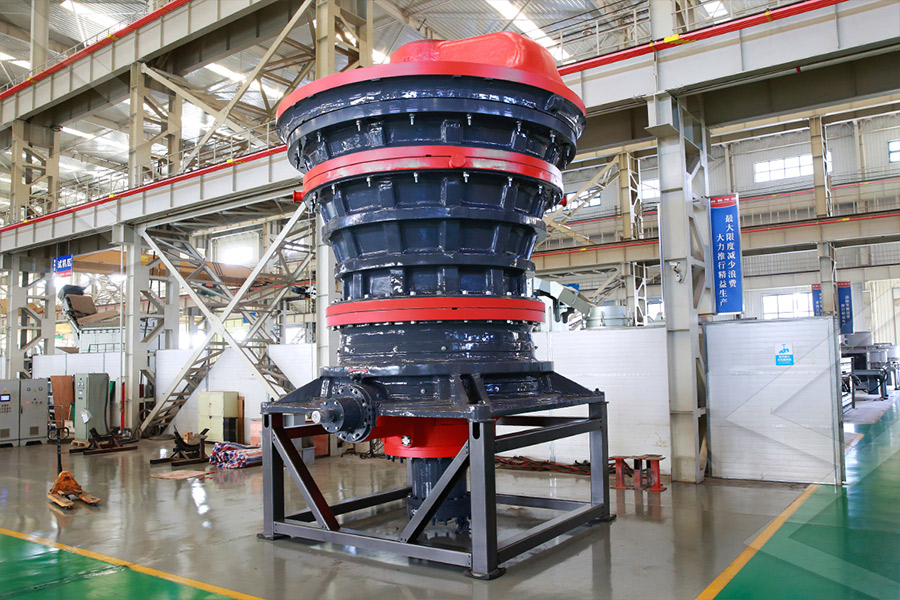

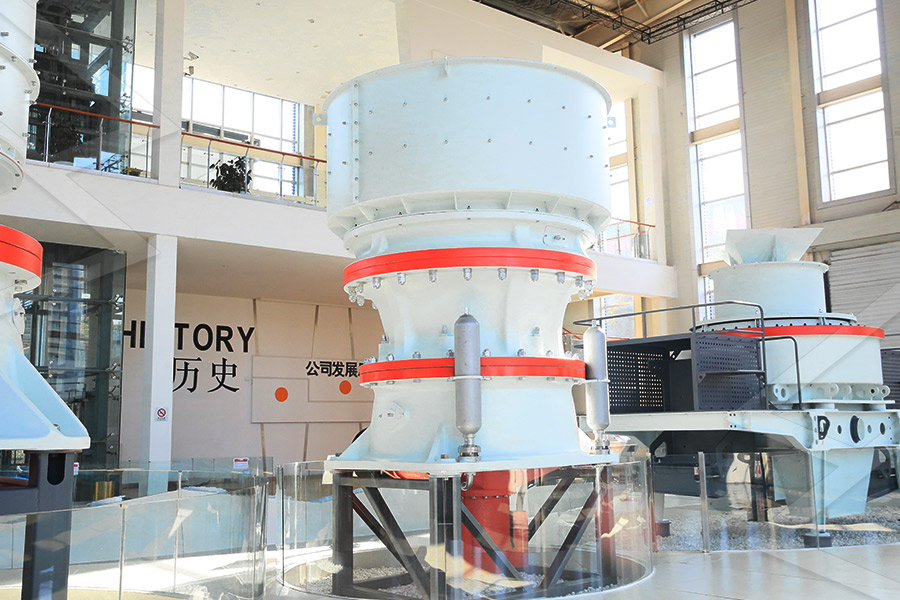

WebOur hammer mills reduce dry and semimoist materials with a minimum amount of fines and caking or plastering within the crusher They are ideal for granulated and pelletized materials Hammer mills utilize a central rotating shaft, affixed with several “hammers” on pivots attached to the shaft As the shaft spins, the hammers are swung via WebIf your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been designing, manufacturing and creating innovative solutions for large and small customers all over the worldFine Grinders, Hammer Mills, and More for Particle Size Reduction

Hammer Mills Hosokawa Alpine

WebHammer Mill To the machine Highspeed hammer mills designed for continuous operation in harsh environments at peripheral speeds of up to 100m/s Your contact Please tell us your area of interest and where you are from Planning the entire process It’s not just building a machine – we support your projects from consulting to maintenance WebHammer Mill HM 200 Rugged design meets high final fineness Hammer mills are used for crushing, pulverizing and deagglomeration of mediumhard, hard, brittle, tough and fibrous samples The rugged RETSCH Hammer Mill HM 200: For Laboratory Pilot Plant ::

Hammer Mill Crusher Grinder Mineral Processing

WebFeb 25, 2016 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion WebOur hammer mills reduce dry and semimoist materials with a minimum amount of fines and caking or plastering within the crusher They are ideal for granulated and pelletized materials Hammer mills utilize a central Hammer Mills FEECO International Inc

Hammer mill Wikipedia

WebA hammer mill, hammer forgeor hammer workswas a workshopin the preindustrial erathat was typically used to manufacture semifinished, wrought ironproducts or, sometimes, finished agricultural or mining tools, or military weaponsWebThe 34″ x 24″ HD hammer mill is rated to accept feed of this type of looselyheld material at up to 20lbs per piece The 24″ x 16″ HD hammer mill is good for up to 68 lbs per piece We recommend that heavy Hammer Mills Heavy Duty (HD) Class Mt Baker

Understanding the Working Principle of Hammer Mills

WebJun 15, 2020 Hammer mills can effectively reduce raw material to desired sizes as needed, from mediumsized particles to ultrafinesized particles Whether food pellets for livestock feed, granules of sugar, spices or WebThe HammerMaster is a highspeed mill noted for its ability to generate highquality aggregates, cubical in shape, with superior soundness Available in three sizes, the HammerMaster is known for making excellent asphalt chip material, concrete stone, and general base material and road rockHammermill Crushers McLanahan

Used Hammermill pulverizers Machinio

WebSteel hammer mill grinding machine Mfd by Schepens (Belgium), Type Gladiator, Size 3 Shaft speed 4500 rpm W/ (16) swing hammers Chamber 300mm dia x 250mm wide Feed 250mm x 100mm Feed end has Erietz magnetic Princeton Junction, NJ Click to Request Price Trusted Seller Williams Patent Crusher Pulverizer Co Meteor 40 High Speed WebJul 29, 2022 The history of the hammermill dates back over 1,500 years to the 5 th century Unlike the hammermills used today, these machines were most often used to create weapons or for mining In 488 AD, the Chinese inventor and engineer Zu Chongzhi invented a waterpowered hammermill The increased power generated by powerful river currents A Brief History of the Hammermill West Salem Machinery

Roller Mill vs Hammer Mill RMS Roller Grinder

WebSep 15, 2022 Energy efficiency is becoming a top priority for many mill owners, and roller mills are typically around 25 to 30% more energy efficient than their hammer mill counterparts Unlike a hammer mill, a roller mill doesn’t require an air assist system to pull material through the filtering screens With a hammer mill, a lot of extra electricity is WebA hammer mill is a singlepassagetype mill that has sets of hammers (generally rectangular pieces of hardened steel) spaced equally and attached to a rotating shaft that rotates at high speed using a powerful electric motor inside a grinding chamber The leading face of the hammers may be blunt or sharp to create different impact or shearing Hammer Milling Baking Processes BAKERpedia

Industrial Hammer Mill Crusher Stedman Machine

WebWood hammer mills, also called wood hogs are special heavy duty Stedman Hammermills specifically designed to process wood and fibrous waste without the use of high maintenance knives Our machines have simple designs with rugged construction that make them easy to operate and maintain Have Questions? Ask Our Experts Features Benefits