石膏粉的生产流程,水泥生产工艺流程

2021-11-17T14:11:11+00:00

石膏制粉的加工工艺流程 知乎 知乎专栏

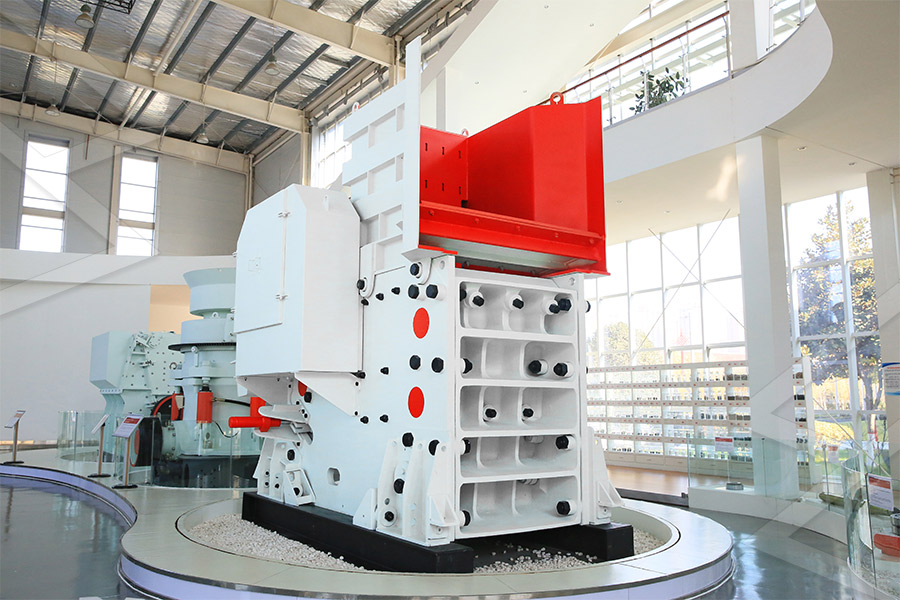

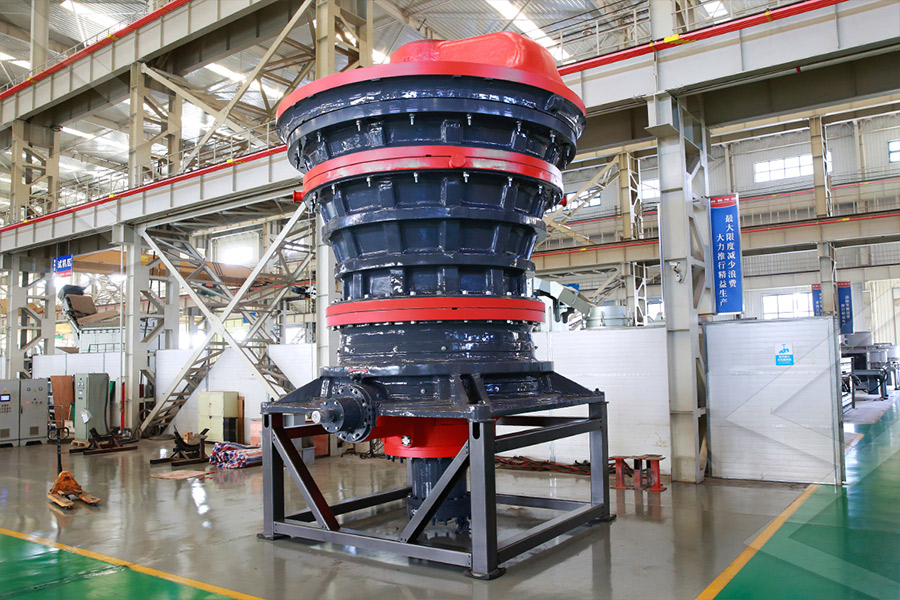

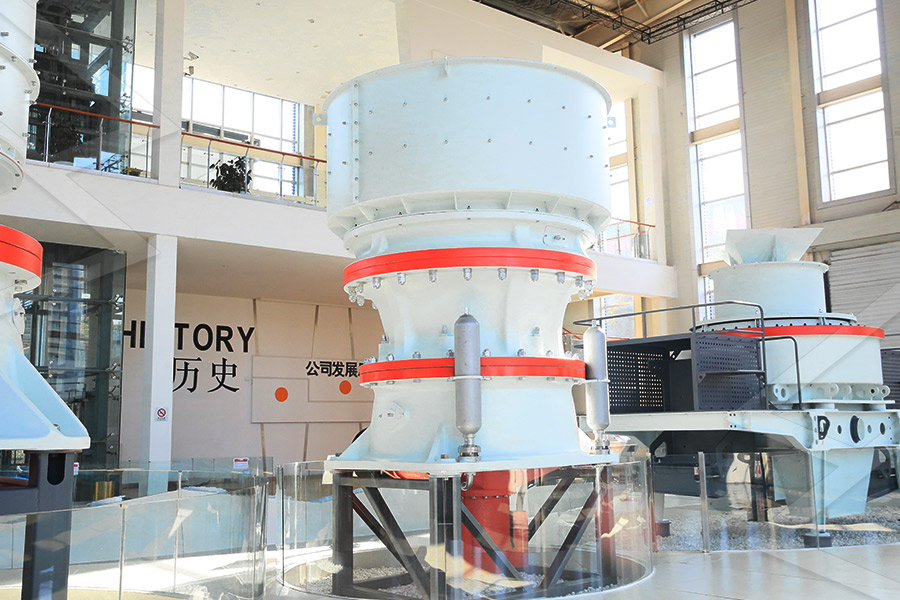

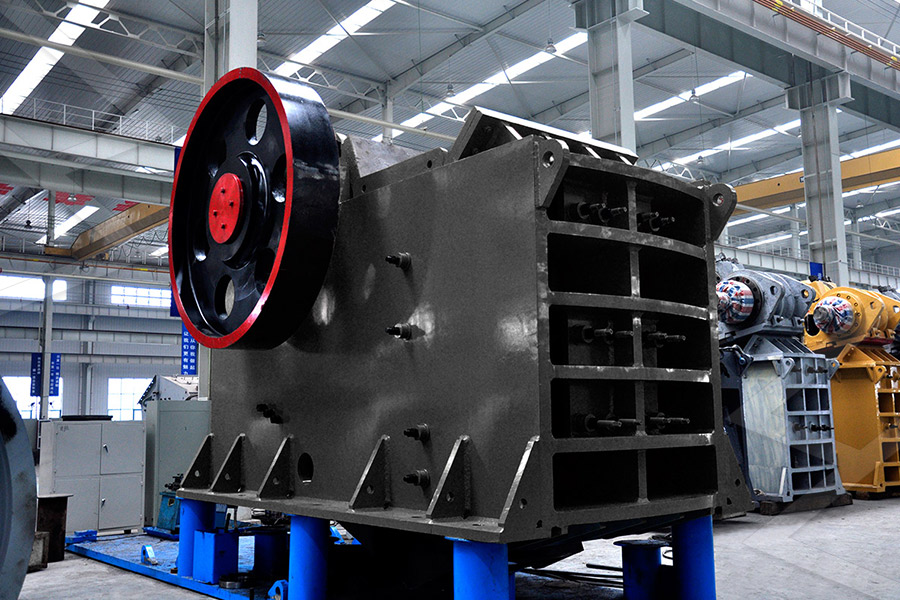

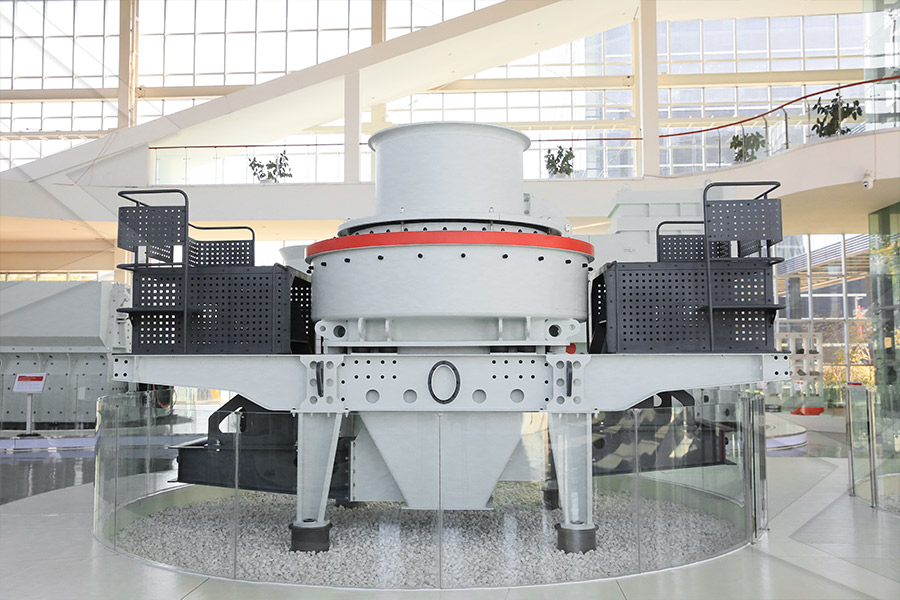

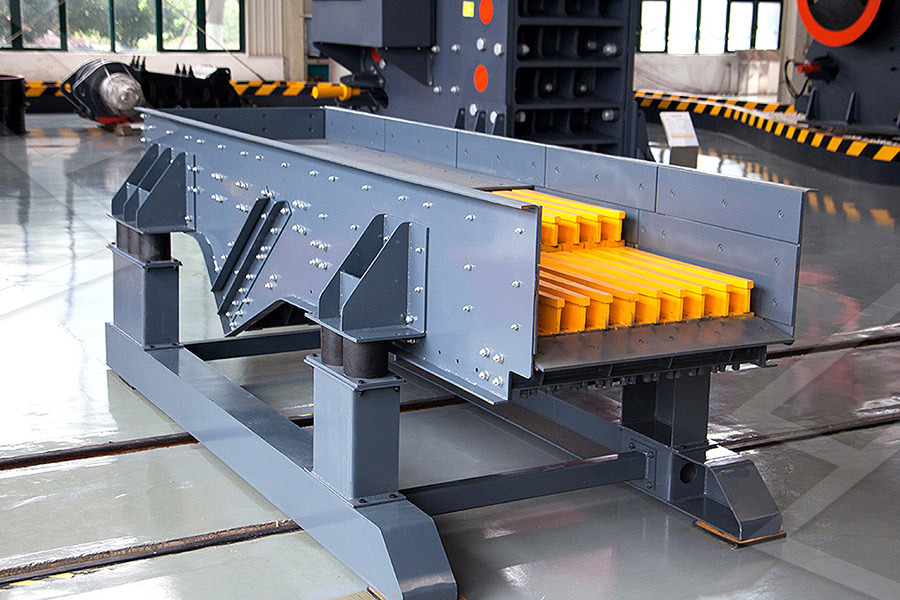

Web工艺流程一 石膏粉生产线采用国内成熟先进的工艺设备,如立式磨粉机、沸腾炉等 工艺流程二 破碎机将大尺寸的石膏矿石破碎成小于30mm的小块颗粒,输送至磨机进行粉磨 工艺 Web石膏粉的生产工艺流程基本可分为三个阶段:破碎、研磨、煅烧。 石膏粉生产流程 破碎阶段 经开采的石膏矿石大小规格不一,根据实际情况选择适用的破碎设备进行初步破碎处 破碎、研磨、煅烧——石膏粉生产工艺流程 知乎

水泥生产工艺流程 百度文库

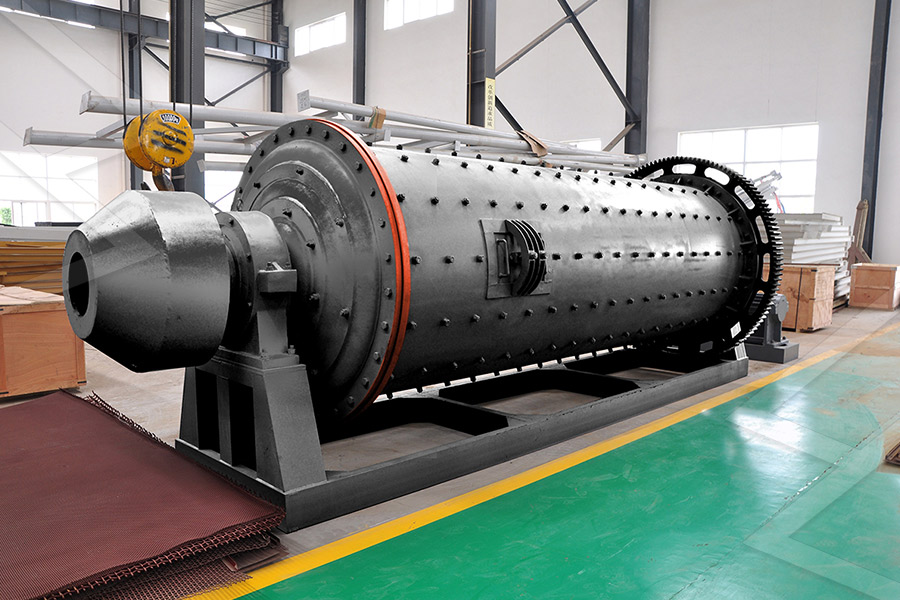

Web水泥生产工艺流程 1、破碎及预均化 (1)破碎 水泥生产过程中,大部分原料要进行破碎,如石灰石、黏土、铁矿石及煤等。 石灰石是生产水泥用量最大的原料,开采后的粒度较 WebJun 17, 2012 关注 水泥生产工艺流程 1、水泥原料的破碎及预均化 (1)破碎 水泥生产过程中,大部分原料要进行破碎,如石灰。 (2)原料预均化 使原料堆场同时具备贮存与 水泥制造工艺流程 百度知道

石膏粉生产工艺流程简介 – 聚合猫

WebJul 2, 2020 石膏粉生产工艺流程可归纳为:石膏矿石→振动给料机→颚式破碎机→斗式提升机→原材料仓→磨粉机→斗式提升机→沸腾炉→斗式提 WebOct 27, 2021 水泥生产工艺流程简图 水泥生产流程较复杂,需要对原矿石破碎磨粉预均化生料制备生料预热和分解熟料烧制水泥磨粉包装,整体如下图所示,用到的主要矿石 水泥生产工艺流程有哪些?附生产工艺简图天宇重工

石膏粉生产工艺流程图(粉刷石膏生产工艺流程图片) – 碳资讯

WebApr 14, 2022 α型熟石膏的生产工艺 (1) 蒸压法 按脱水与干燥是否在同一设备内进行,又可分为下列两法: ①将块状石膏置于金属网篮中放入蒸压釜内,在13~3大气压蒸 Web水泥生产全过程一般分为四个阶段: 1、矿山开采: 即通过对石灰石矿进行开采、破碎,并通过各种方法运输至石灰石库的过程。 2、生料制备: 即石灰石原料与少量粘土质原料 怎样制造水泥? 知乎

水泥生产流程百度经验

Web新型干法水泥生产线指采用窑外分解新工艺生产的水泥。其生产以悬浮预热器和窑外分解技术为核心,采用新型原料、燃料均化和节能粉磨技术及装备,全线采用计算机集散控制, Web石膏原矿→破碎→磨粉→反应釜(加水与药剂)→清洗→脱水干燥→包装。 石wenkubaidu的生产工艺流程 β型熟石膏的生产工艺流程一般是:矿石储存→破 石膏的生产工艺流程 百度文库

process flow chart of gypsum roasting przegladbiznesueu

Webprocess flow chart of gypsum roasting T11:09:34+00:00 Gypsum Board production flow YOSHINO GYPSUM Click here to see the principle on how gypsum solidifies Chemical reaction of 窶徃ypsum窶・/a> 2 Molding process Calcined 窶徃ypsum窶・is mixed with water to make a slurry (muddy state) Then, the slurry is poured into a WebBurning And Grinding Of Cement ekliefkrismiscoza cement grinding burning appli ion – Grinding Mill China Burning And Grinding Of Cement Chapter 1 Introduction to Cement Production The wet process of fine grinding is the older process, The manufacturing of cement generally involves four steps: Mixing; Burning; Grinding; Storage; Mixing: The burning and grinding of cement

the process of cement production

WebJul 23, 2021 水泥生产工艺流程(Cement production process)doc In a Portland cement plant, cement production has the following major stages: Preparation of raw materials Limestone is the main raw material for cement production, and most factories are located near limestone quarries in order to minimize transportation costsWeb水泥生产工艺流程(Cement production process)doc 水泥生产工艺流程(Cement production process)doc,水泥生产工艺流程(Cement production process) Cement production process Author: site data collation unit: [] Key words: cement production Abstract: Those who know a little about cement production processing

grinding cement into powder

Web水泥生产工艺流程(Cement production process)doc In the clinker grinding process, clinker and other raw materials be ground into fine powder, as many as 5% of the gypsum or anhydrite added to be added, in order to control cement solidification time, at the same time with other compounds, for example, used to Get PriceWebCement Production Max Cement Max Cement production capacity is 2100 ton per day by using international equipped machines plus qualified raw materials such as limestone, laterite, clay and coal Packaging System 50 kg filled per cement bag has been better structure packing bags for moisture resistance and heavy load Max Cement TEL FAX cement production system

clinker grinding preparation impact crusher ma

WebThe Qingzhou 6000T/D Cement clinker production project of Zhonglian Cement Co, Ltd mainly includes the following 4 systems: Raw material grinding and waste gas treatment system: including limestone crushing and transportation, limestone storage and transportation, auxiliary raw material 水泥生产工艺流程(Cement production process WebSchematic of cement production process Ohorongo This is a schematic presentation of the whole cement manufacturing process Raw materials such as limestone, shale and marl are collected at the quarry and transported to the crusher where they are crushedcement production process presentation Mineral de hierro

used to grind cement

WebHow to Grind 1 Inch of Concrete: In 3 Steps [Effectively] Concrete grinders are 2 types, which are walkbehind concrete grinder and handheld concrete grinder 1 Walkbehind Concrete Grinder: These grinders are powerful and come with more speed options compared to handheld concrete grinders A range of choices is also available for concrete WebSmall Cement Grinding Machine And Unit T23:05:03+00:00 Home Small Cement Grinding Machine And UnitSmall Cement Grinding Machine And Unit MC Machinery

cement plant process chart

Webcement plant process chart T07:08:21+00:00 Cement Manufacturing Process Simplified Flow Chart Cement Manufacturing Process Simplified Flow Chart March 15, 2017WebCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s of airseparator for cement mill

cement production processes

Webcement production processes T00:04:12+00:00 The Cement Manufacturing Process Thermo Fisher Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement WebAll Mobile crushing line Stationary crushing line Industrial grinding lineMENT CLINKER MILLING EQUIPMENT PRODUCTION

cement production processing

Web水泥生产工艺流程(Cement production process)doc 水泥生产工艺流程(Cement production process)doc,水泥生产工艺流程(Cement production process) Cement production process Author: site data collation unit: [] Key words: cement production Abstract: Those who know a little about WebSchematic of cement production process Ohorongo This is a schematic presentation of the whole cement manufacturing process Raw materials such as limestone, shale and marl are collected at the quarry and transported to the crusher where they are crushedcement production process presentation Mineral de hierro

cement production system

WebCement Production Max Cement Max Cement production capacity is 2100 ton per day by using international equipped machines plus qualified raw materials such as limestone, laterite, clay and coal Packaging System 50 kg filled per cement bag has been better structure packing bags for moisture resistance and heavy load Max Cement TEL FAX Webcement plant process chart T07:08:21+00:00 Cement Manufacturing Process Simplified Flow Chart Cement Manufacturing Process Simplified Flow Chart March 15, 2017cement plant process chart

cement grinding delivery

Web水泥生产工艺流程(Cement production process)doc The grinding process is carried out in a closed system equipped with an air separator for separating cement particles according to size, and materials which are not completely ground are sent back to the system This high energy consuming process requiresWebUnderstanding Limestone in Cement Concrete The added limestone in the US is modern portland cement and consists of ground clinker, a source of readily soluble sulfates and functional additiveswhy limestone is used in clinker grinding

水泥流程图 ascsfr

WebProducts AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plantWebPrimary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile station粉煤灰水泥生产流程图

Small Cement Grinding Machine And Unit MC Machinery

WebSmall Cement Grinding Machine And Unit T23:05:03+00:00 Home Small Cement Grinding Machine And UnitWebPrimary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile station石膏粉的工艺流程

how many cement is fine grinding

WebEnergy saving with separate fine grinding CemNet Energy saving with separate fine grinding Separate grinding and subsequent blending is a commonly used practice in the cement industry, enabling the lowering of the specific electric energy demand by using highly efficient comminution techniques While ball mills are not the most energyefficient mills, WebCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s of airseparator for cement mill

clinker grinding preparation impact crusher ma

WebThe Qingzhou 6000T/D Cement clinker production project of Zhonglian Cement Co, Ltd mainly includes the following 4 systems: Raw material grinding and waste gas treatment system: including limestone crushing and transportation, limestone storage and transportation, auxiliary raw material 水泥生产工艺流程(Cement production process WebProducts AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant水泥磨粉站的主要生产工艺过程